Three major advantages – to say goodbye to traditional fabrics

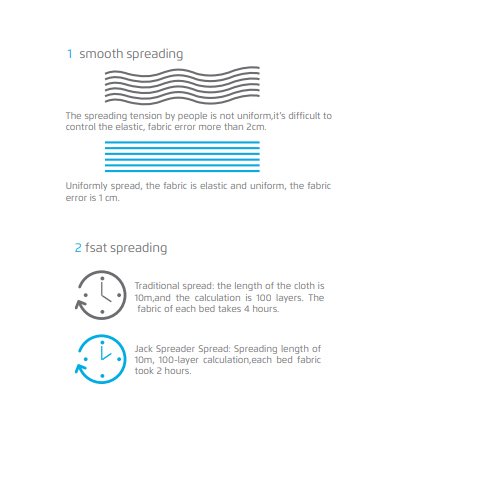

1: Smooth spreading

- The spreading tension by people is not uniform, and it’s difficult to control the elastic, fabric error of more than 2cm

- Uniformly spread, the fabric is elastic and uniform, and the fabric error is 1 cm

2: fast-spreading

- Traditional spread: the length of the cloth is 10 m, and the calculation is 100 layers. The fabric of each bed takes 4 hours.

- Jack Spreader Spread: Spreading length of 10 m, 100-layer calculation, each bed fabric took 2 hours.

3: Make more money

- 2 workers for spreading cloth1-bed fabric /day, 2 groups, 4 workers labour wage:4000 yuan/month X 12 months X 4 workers=192000 yuan/year for personnel management: 1000 yuan/month X 12 months X 4 workers=48000 yuan/ year = Total cost: 240000yuan/ year

- 1 worker 1 spreading machine 4-bed fabric /day, 1 worker labour wage:4000 yuan/month X 12 months X 1 worker=48000 yuan/ year Cost for personnel management: 1000 yuan/month X 12 months X 1 worker=12000 yuan/ year = Total cost: 60000 yuan/ year

Suitable for both knitted and woven fabrics

Automatic Spreader uses the PLC control system, applied for high-precision tension-free spreading of knitted and woven fabrics. The multi-spreading device guarantees smooth spreading. Tightness adjusting uses servo control, people can precisely adjust the tightness of spreading cloth. There is also a tightness parameter memory function. With optional devices, several spreading ways can be achieved, such as one-way spreading, zig-zag spreading, etc.

- precision: Servo motor control greatly improved the spreader’s positional and fabric feeding accuracy; The traditional mechanical elastic adjuster is replaced by electronic parameter mode, which has higher precision and is easy to control. The optional devices can be achieved in several ways: one-way spreading, zig-zag spreading, and single pull-cutting, suitable for a variety of fabrics.

- convenient maintenance: The automatic spreading machine applies the servo control system of the former ordinary motor sprockets control system, which is simple in structure and easier to maintain.

- variety of optional devices: Through the optional devices can be achieved several spreading ways: one-way spreading, zig-zag spreading, and single pull-cutting, suitable for a variety of fabrics.

| Machine size (mm) | 2630*1900*1000 | 2830*1900*1000 | 2930*1900*1000 |

| Maximum cloth width | 1900mm | 2100mm | 2200mm |

| Table width | 2130mm | 2330mm | 2430mm |

| Lay height | one-way:220mm | zigzag:150mm | |

| Machine weight | 340kg | 360kg | 380kg |

| Diameters of cloth roll | 600mm max | 60kgmax | |

| N.W/G.W | 495/755kgs | ||

| Travel speed | 94m/min max | ||

| Power supply | 1p/220v | ||