1-needle lockstitch machine with automatic functions, bottom feed and energy-saving motor built into the machine head (Direct Drive). The automatic response to the change in the thickness of the sewn material and the combination of material feed correlation and needle insertion force in real-time ensures stable sewing of various materials without the need to adjust the machine. The machine, like the previous A5 versions, is characterized by an elongated body – the distance from the needle to the body is 30.5 cm.

Automatic functions:

- thread cutting

- lifting the presser foot

- bartacking while sewing

- needle positioning

- sewing according to programmed sections

The machine uses a stepper motor that controls the setting of the stitch length in the machine and is also responsible for the locking function. The “Octopus Nine-brain” artificial intelligence chip is an intelligent solution that ensures an automatic change of machine parameters according to the thickness of the sewn material in real time. Closed lubrication system (no typical oil sump). A small amount of oil in a closed circuit. This solution guarantees lower oil consumption and better lubrication of mechanisms. The motor with increased power with increased torque guarantees adequate breakthrough power even when sewing thicker materials in multiple layers. The Jack A5E-A lockstitch machine has a thread trimming system that shortens the length of the thread after trimming to 3.5 mm.

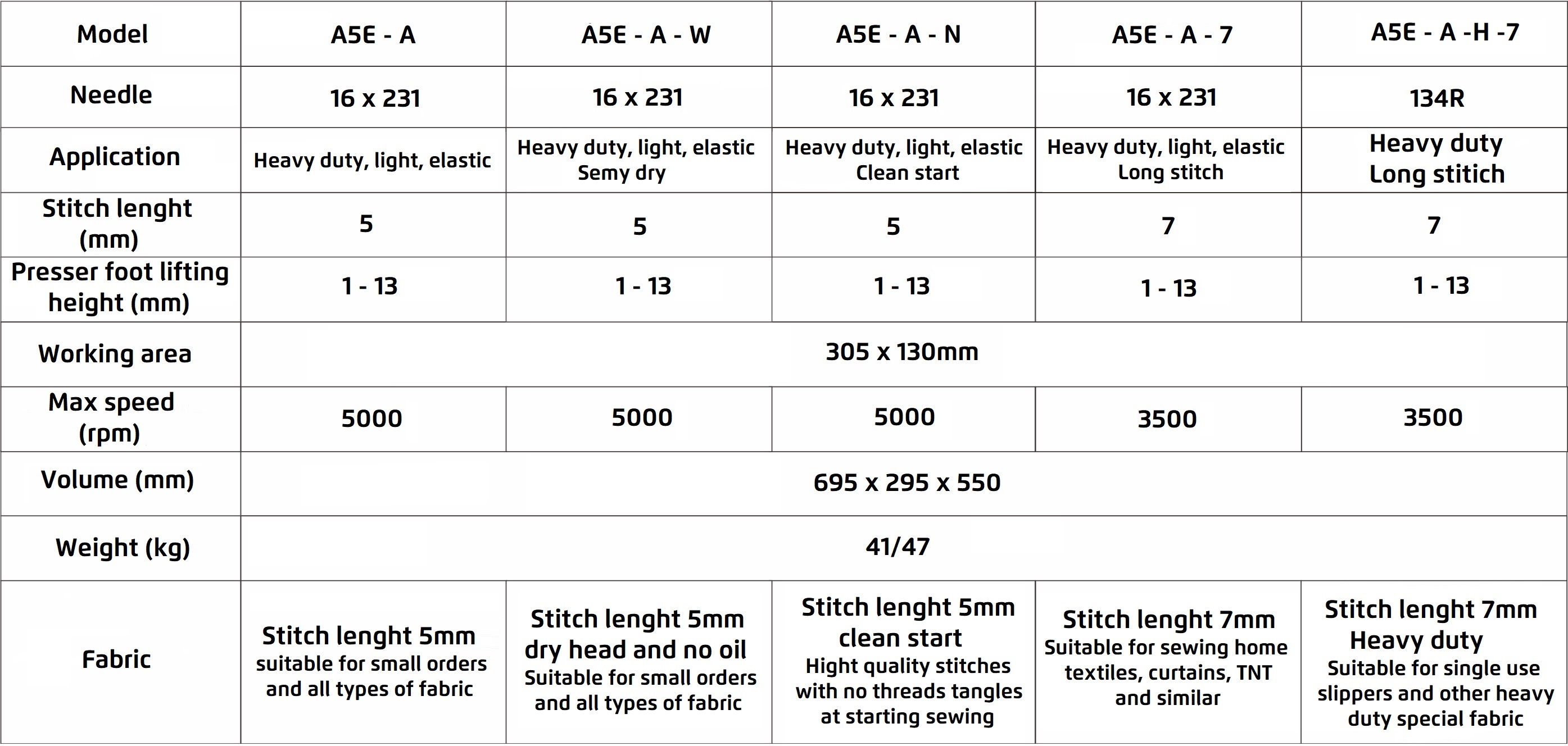

Technical parameters:

- sewing speed: up to 5000 stitches/min

- stitch length: up to 5 mm

- presser foot lift: up to 13 mm

- three function buttons located at the needle bar: 1/2 of the stitch length, adding a stitch, bartacking

- USB port for connecting external devices